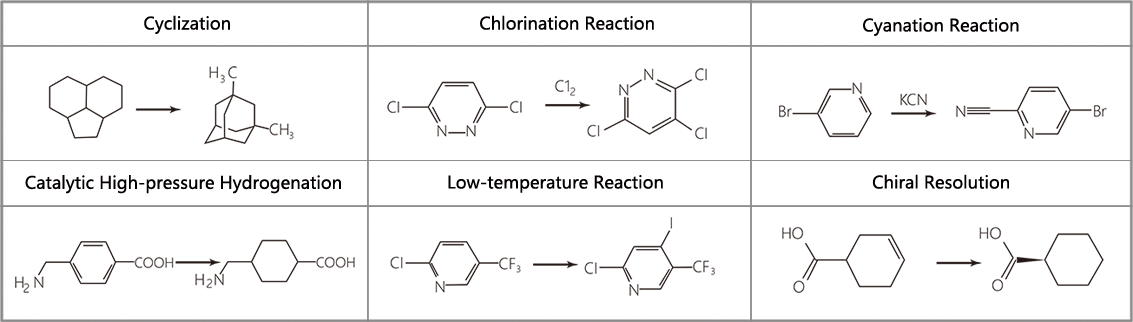

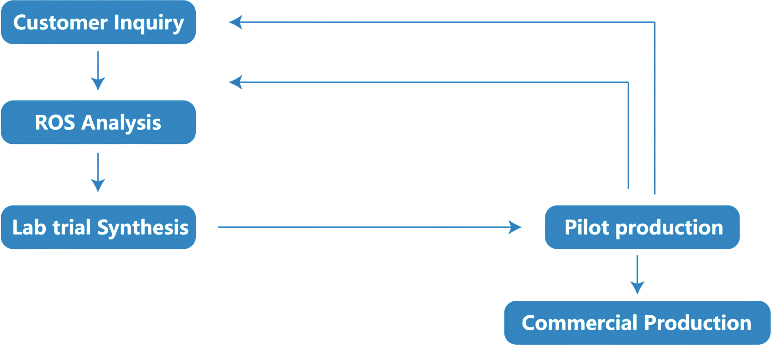

Our state-of-the-art and technology enable delivery a full custom synthesis and manufacturing service in a growing number of markets. The available business model includes:

Molecular inquiries: ROS development, chemical process optimization and molecular synthesis.

Custom synthesis: Pr ocess optimization and scale up.

Toll manufacturing: Process optimization and manufacture in plant facility.

Contracted process development for customers is available on request.

— Multiple reactor sizes ranging from 50 to 2000 L

— Agitated pressure filters, centrifuges and notches

— Acid and alkaline resistant equipment

— Temperature ranging from - 80°C to 250°C

— Pressure ranging from 2mbar to 40 bar

— Finish product handling/ drying in controlled areas

We protect our customer' s confidentiality information by strict control over the use of manufacturing processes. All of our employees are required to execute confidentiality and non-disclosed agreement with the company, The access to protected data in the projects are limited in authorized personnel to prevent unintended disclosure.

— Under confidential agreement, below docs for vendor qualification and GMP/DMF filings etc. requirements.

— Route of synthesis with solvents, reagents, raw materials and catalyst data used in each stage

— Flowchart with solvents, reagents, raw materials and catalyst data used in each stage

— List of solvents, reagents, raw materials and catalyst data used in each stage

— Brief manufacturing process

THE PRODUCTS UNDER VALID PATENT PROTECTION ARE OFFERED FOR

R&D ACTIVITES ONLY, NO COMMERCIAL USE.

Reg Office: Room 435, Building 9, No.2568 Gudai Road, Minhang District, Shanghai, China.

Pilot Lab: Building 1, No. 589 Qinling Street, Shijiazhuang High-tech Zone,Hebei, China.

Plant Unit 1: Xincheng town clean chemical park, Xinji, Hebei, China.

Plant Unit 2: Dongming County South Chemical Park, Heze City, China.

Tel: +86-21-34943721

WhatsApp:+86 186 1680 6816

Email:Massive@massivechem.com

Info@massivechem.com

Shanghai Massive Chemical Technology Co., Ltd. All Rights Reserved(C)2023 Supported by Record number:沪ICP备18008139号