Wood finishing is the process of refining or protecting a wooden surface and is the final step in the overall manufacturing process. A good wood finish is recognized by providing several clear benefits which include protection against abrasion caused by dirt, damage caused by heat, and protection against the evaporation of moisture which can potentially change the structure of the wood surface itself if left unprotected. However, achieving all of these doesn’t come without a cost. There are various ways to finish and coat wood that have been utilized over the past several decades but one recurring issue that has been a part of the wood finishing process is the negative effects the process takes on the environment.

What are the Harmful Effects of Conventional Wood Finishes

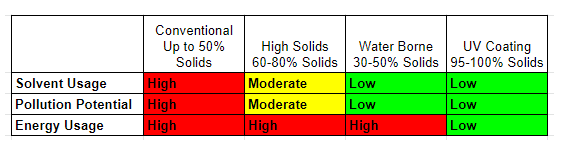

Conventional wood finishes, such as those based on oil or water, release high levels of solvents that are classified as volatile organic compounds (VOCs), which have not only been shown to reduce the quality of indoor air found in homes, but can also lead to harmful health effects. One of the most common VOCs, formaldehyde, is found in most conventional wood finishes. Exposure to formaldehyde has been shown to lead to harmful side effects including irritation to sinuses, headaches, nausea, and damage to organs such as the liver or the kidney. So not only are VOCs bad for the environment but they are also a threat to your own health. On one last note, conventional wood finishes uses high amounts of energy which in turn has a negative impact on the environment. So how can we avoid the issue of contributing negatively to both the overall environment and the air quality found within your own home?

Why UV Coating is Eco-Friendly

UV coating is a type of wood finish that involves the surface being cured by ultraviolet radiation. Unlike typical wood finishing processes that use heavy amounts of harmful solvents and VOCS, 100% UV radiation coating uses little to no VOCs in the process. The end result is a process that is able to create a nice, clean finish that gives protection from heat, moisture, and dirt, and allows for a pleasant, glossy aesthetic of the wood itself. All of this is achieved without contributing negatively to the environment and allows for a product that avoids releasing harmful chemicals into your personal home. Not to mention, another benefit of the UV coating process when compared to other methods is that the amount of energy used is significantly lower than standard wood finishing processes.

Reg Office: Room 435, Building 9, No.2568 Gudai Road, Minhang District, Shanghai, China.

Pilot Lab: Building 1, No. 589 Qinling Street, Shijiazhuang High-tech Zone,Hebei, China.

Plant Unit 1: Xincheng town clean chemical park, Xinji, Hebei, China.

Plant Unit 2: Dongming County South Chemical Park, Heze City, China.

Tel: +86-21-34943721

WhatsApp:+86 186 1680 6816

Email:Massive@massivechem.com

Info@massivechem.com

Shanghai Massive Chemical Technology Co., Ltd. All Rights Reserved(C)2023 Supported by Record number:沪ICP备18008139号