UV curing technology is a high-efficiency, environmentally friendly, energy-saving, advanced technology in the 21st century, which is widely used in coatings, adhesives, inks, optoelectronics and other fields.

Since the American Inmont company obtained the first UV curable ink patent in 1946, and the German Bayer Company developed the first generation of UV curable wood coatings in 1968, UV curable coatings have developed rapidly all over the world. In recent decades, a large number of new and efficient photoinitiators, resins, monomers and advanced UV light sources have been applied to the UV curing industry, which has promoted industry development.

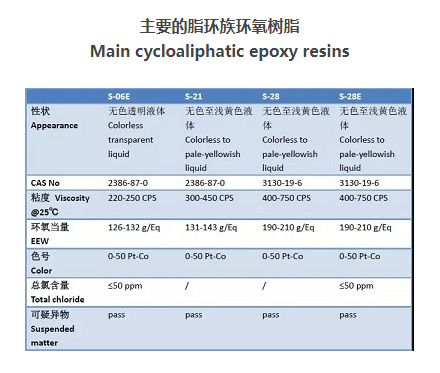

The cycloaliphatic epoxy resin is a low molecular compound containing two cycloaliphatic epoxy groups. It is not a polymer itself, but when reacting with the curing agent it can generate a polymer with excellent-performance three-dimensional structure. Advantages include low viscosity, good thermal stability, low halogen content, great electrical performance, excellent UV-resistant and non-yellowing performance, low migration and no oxygen inhibition after UV curing, etc.

2-Propenoic acid,4-benzoylphenyl ester is a kind of photoinitiator and a polymer additive used in UV curving industry.

Shanghai Massive Chemical Technology Co., Ltd. has years of experience in the production of photoinitiators. We are committed to providing customers with stable production capacity, reliable product quality and considerate service. Welcome customers at home and abroad to contact us!

Reg Office: Room 435, Building 9, No.2568 Gudai Road, Minhang District, Shanghai, China.

Pilot Lab: Building 1, No. 589 Qinling Street, Shijiazhuang High-tech Zone,Hebei, China.

Plant Unit 1: Xincheng town clean chemical park, Xinji, Hebei, China.

Plant Unit 2: Dongming County South Chemical Park, Heze City, China.

Tel: +86-21-34943721

WhatsApp:+86 186 1680 6816

Email:Massive@massivechem.com

Info@massivechem.com

Shanghai Massive Chemical Technology Co., Ltd. All Rights Reserved(C)2023 Supported by Record number:沪ICP备18008139号