Traditional coating uses "chemical solvent" serve as diluent, also call so "solvent-based coating", waterborne paint uses water to serve as diluent, call for "waterborne coating", and UV coating is named with the solidified means of paint. It is a coating that can quickly solidify into a film in a few seconds under ultraviolet (UV) irradiation. UV coating is automatic roller coating through machinery and equipment, spraying to furniture board surface, under the irradiation of UV light to promote the decomposition of initiator, free radical, trigger resin reaction, instant curing film, no solvent volatilization, so more efficient, green, environmental protection.

The value of using UV paint comes from four aspects: First, in line with the national environmental protection policy, to promote the government docking and business level more smoothly; Second, it can meet the consumers' pursuit of "health and environmental protection" in the market and get the first opportunity in marketing; Third, in the care of employees, it will greatly improve the VOC hazards in the coating construction environment, is beneficial to the health of employees; Fourth, because the curing time of UV coating is short, mechanized equipment overcomes the artificial factors in manual operation, quality is stable, production efficiency is high.

UV coating advantages: (1) the green environmental protection: the solid content of 100%, excluding the volatilization of solvent (2) high efficiency, is advantageous for the mechanized operation, the instantaneous curing, logoff stackable (3) performance is good, high hardness, good abrasion resistance and stable products (4) save resources: save a large amount of manpower, space, decrease the cost of the coating (5) convenient construction, construction is convenient, and there is no time limit should be used.

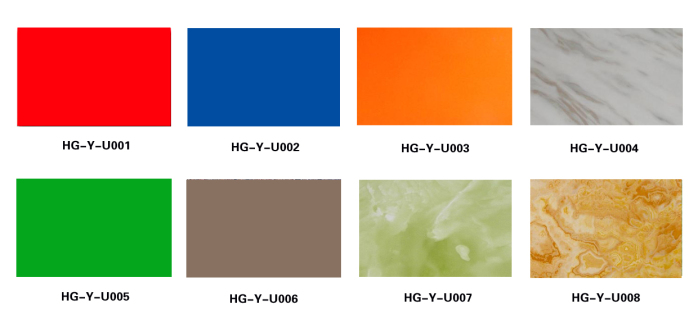

At present, with the increasing pressure of environmental protection, UV coating has gradually been widely used, but different construction methods are suitable for different segments of the field. Spraying method: furniture, cosmetics, electronic plastic shell; Roller coating method, drenching method: PVC board, panel furniture, wood floor, etc.; Screen method: paper, etching ink, etc.; Dip coating method: complex components such as arts and crafts; Swing coating method: CD records and other materials; Brush coating method: wood, circuit board, nail, etc.

Generally speaking, the unit price of UV coating is slightly higher than the traditional solvent based coating, plus the early investment in equipment, the cost will increase. But in the long run, due to the mechanization of UV coating coating, improve the utilization rate of paint, reduce the waste of paint, reduce the cost of use. Under the same solid content, no product has more advantages than UV roller coated products.

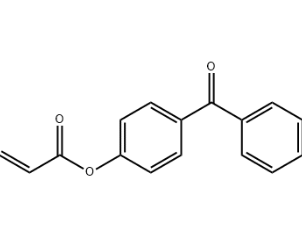

4-Benzoylphenyl acrylate is a kind of photoinitiator with great value in UV coating fields. 4-Benzoylphenyl acrylate is also named as 4-Acryloxybenzophenone; 4-Benzoylphenylacrylate; 4-Acryloyloxybenzophenone; (4-benzoylphenyl)prop-2-enoate; 4Chemicalbook-Benzoylphenylacrylatefandachem; 2-Propenoicacid,4-benzoylphenylester; 2-Propenoicacid,4-benzoylphenylester

Reg Office: Room 435, Building 9, No.2568 Gudai Road, Minhang District, Shanghai, China.

Pilot Lab: Building 1, No. 589 Qinling Street, Shijiazhuang High-tech Zone,Hebei, China.

Plant Unit 1: Xincheng town clean chemical park, Xinji, Hebei, China.

Plant Unit 2: Dongming County South Chemical Park, Heze City, China.

Tel: +86-21-34943721

WhatsApp:+86 186 1680 6816

Email:Massive@massivechem.com

Info@massivechem.com

Shanghai Massive Chemical Technology Co., Ltd. All Rights Reserved(C)2023 Supported by Record number:沪ICP备18008139号