Photoinitiator is a molecule that can absorb radiation and produce active intermediates with the ability to initiate polymerization through photochemical changes. When the photoinitiator initiates the polymerization of prepolymer and monomer, it becomes part of the polymer structure to cure the film, and part of it does not participate in the curing film.

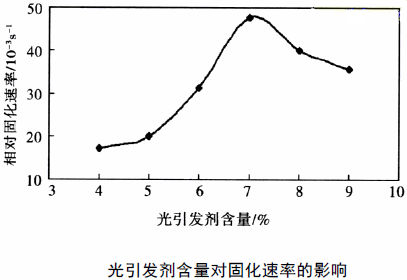

The influence of the concentration of photoinitiator on the curing rate is shown in the figure. It can be seen from the figure that when the concentration of photoinitiator is 7%, the UV light intensity required is the lowest, that is, the curing rate is the fastest, but when the concentration is increased, the curing rate decreases.

Two problems arise when photoinitiator concentrations are too high: First, due to the photodecomposition of photoinitiator will produce some non-curing materials, which weaken the chemical resistance and physical properties of the coating; Two, the concentration of photoinitiator is high, the ratio of the polymerization rate of the surface and the polymerization rate of the coating body increases, and different stresses appear in different thickness of the coating, which will make the coating shrink, but also lead to fracture in the curing structure and the adhesion of the curing layer and the substrate is not firm.

The selection of photoinitiator is considered from the following aspects:

1.Price: different photoinitiator price difference dozens of times;

2.Color: Some photoinitiators produce colored substances after light decomposition, such as benzaldehyde;

3.Odor: For example, benzoyl, dimethylketal, reaction to generate methyl formate, can not be used for food packaging;

4.Corrosive: For example, acetophenone derivatives react to produce hydrochloric acid;

5.Stability: Benzophenone and its derivatives have good stability, while benzoyl dimethylketal has poor stability;

6.Curing rate: For example, cheap benzophenone has a very low curing rate;

7.Photoinitiators absorb UV light at different wavelengths.

Reg Office: Room 435, Building 9, No.2568 Gudai Road, Minhang District, Shanghai, China.

Pilot Lab: Building 1, No. 589 Qinling Street, Shijiazhuang High-tech Zone,Hebei, China.

Plant Unit 1: Xincheng town clean chemical park, Xinji, Hebei, China.

Plant Unit 2: Dongming County South Chemical Park, Heze City, China.

Tel: +86-21-34943721

WhatsApp:+86 186 1680 6816

Email:Massive@massivechem.com

Info@massivechem.com

Shanghai Massive Chemical Technology Co., Ltd. All Rights Reserved(C)2023 Supported by Record number:沪ICP备18008139号